Whether your truck is a show piece, a work horse (or a combination of the two), there is little debate as to the importance of a truck bed liner. Aside from the level of protection that it will offer to ensure a longer life for your truck, few would argue the level at which it enhances its looks. After all, there’s no quicker way to make a nice truck look like a piece of crap, than with an exposed (dented, scratched and corroded) bed.

That Wasn’t Always a Problem

By the time the first Ford Model TT rolled off the assembly line in 1917, trucks were purposed for one reason only: work. From farm-to-factory, they were utilitarian in use, and just another tool to get a job done. It would be decades before the mindset toward trucks evolved.

It would begin during the Great Depression, and be accelerated by WWII. With commercial car and truck manufacturing halted to support the war, vehicles were being driven harder and longer. The wear began to show. Exposure to the elements inevitably led to fading and corrosion, and the regularity of use resulted in scratching and denting. Needless to say, the area most victimized was the truck bed.

By the late-40s and early-50s, it was not uncommon to see planks of wood inserted into truck beds. While this had been done by farm workers and laborers for some time, family trucks were following suit. And it wasn’t just being done to hide the age of older trucks, wood planking became a direct-from-factory offering on new truck models.

It would be another thirty years before technology stepped up to meet the demand. In fact, two separate technologies would be utilized, both of which originated during WWII.

Drop-In Bed Liner

Military use only accentuated the increased wear imposed on trucks, already resulting from the infancy of commercial trucking. With trucks carrying more cargo than ever, a solution was needed. That solution rested in the growing prevalence of plastics.

And while plastics had invaded American homes by the sixties, it was the early 80s before the technology used to protect military truck beds was made commercial. The first, and most commercially viable at the time, was the drop-in bed liner.

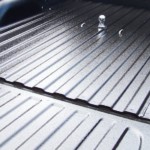

Consisting of thermoformed hard plastic, the drop-in bed liner was a molded cover that slid over the truck bed, fastened usually by bolts or an adhesive. While hardly revolutionary, it served as an early indication of the evolving nature of American trucks. Yes, they were utilitarian, and we needed to protect them from wear; but we also wanted our trucks to look sharp, and hide the signs of wear.

And the drop-in liner would meet most of the challenges. Easy to install, it offered the protection that was required; freshly-installed, it offered an improved aesthetic. The smooth plastics proved durable, and made it easy to slide large objects in and out of the bed.

But with time, the plastic would scratch and fade. Also, the bolt and adhesive-based methods of installation would lead to lifting of the liner, exposing the bed to moisture (and with greater chance of it being collected and trapped under the liner).

Concern over corrosion and wear would be answered by…

Spray-On Bed Liner

The second type of WWII technology that would come into play had originated as urethane-based sprays used to undercoat wartime delivery vehicles and rail cars. While in existence at the same time as the first drop-in bed liner, it would spend more time in research and development, eventually released commercially by the late-80s.

But not all spray-on liners would be equal. Differences in base materials and application process influenced lifespan, wear-resistance and texture, among other traits. This realization would refine, and nearly standardize the practice, resulting in a superior product.

Cleaning and sanding of the bed ensured easier adhesion of the textured coating. Resistance to chipping with no chance of lifting (as seen on drop-in liners) would improve resilience against moisture and corrosion. Resistance to vibration would serve to protect cargo, and the textured surface would help to secure loads.

Also boasting an improved aesthetic, it has become easy to justify (what is normally) a 30-40% increase in cost. Garnering more support, spray-in bed liners would become a factory finish option, whereas drop-in liners remain (primarily) an after-market accessory.

Aside from criticism that the textured surface can make it difficult to load / unload objects, there are few reasons not to consider a spray-on liner, as opposed to a drop-in liner.

Insure to Ensure

Think of it this way. We insure our homes, our vehicles, our health, and even our lives. In general, we believe in taking steps to protect the things we value, ensure them of a long life. This is especially true for items that we utilize everyday, as they are exposed to risk more regularly and run the risk of wear.

Even when walking in and buying a $600 cell phone with two-year service plan, most of us think to purchase a phone case. It just makes good sense. It protects our investment from the conditions it is exposed to (and even from us). So, why would we walk in and buy a $30,000+ truck with the plans of driving it for 5+ years and not protect the exposed area, which will (arguably) get the most use?

That said, a truck liner is like any accessory; there’s no ‘one-size-fits-all’ solution.

Whether you’re focused on aesthetics, durability, longevity, ease of loading / unloading, or security of the load while driving, there are a number of solutions available to you. There may be little debate as to the overall superiority of the spray-in liner as a product and as a protectant; but which one is best for you is something that only you can determine.